Imagine a world where products go from being just a thought in your head to being made real. These are the cool things about additive manufacturing, which is also called 3D printing. This new technology is changing how we plan and make everything from simple household items to complicated aerospace parts.

Long gone are the days when making samples took a lot of time and trial and error. Additive manufacturing services speed up production and make it possible to make changes and tweaks more quickly than ever before. As businesses look into these options, they find new ways to save money that make standard ways of making things less useful.

This blog post will talk about how additive manufacturing isn’t just a trend but a change that’s changing many fields. Learn what it is about this technology that will change everything!

How Additive Manufacturing Services Have Changed Over Time

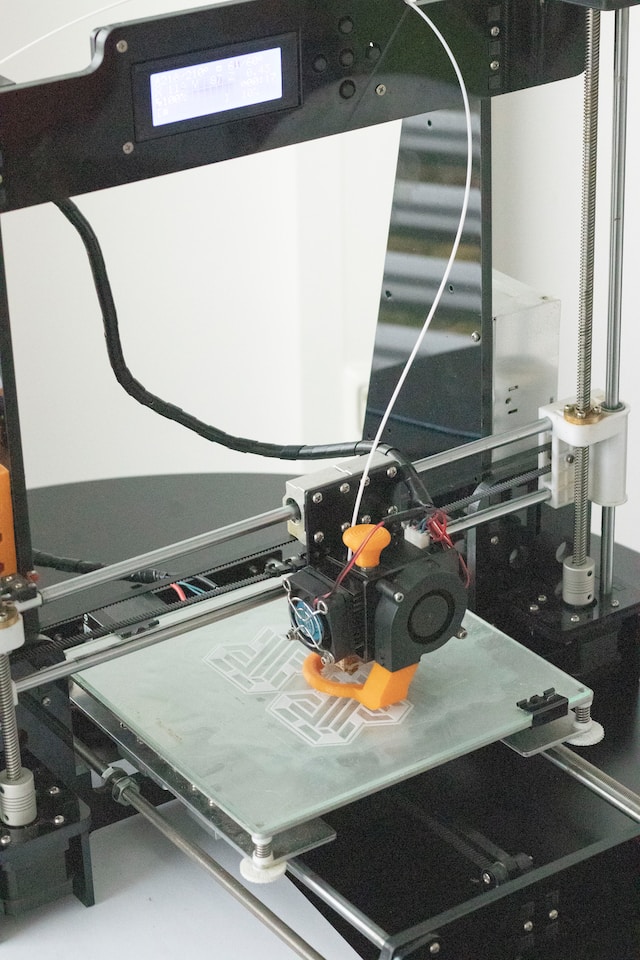

Since its start in the 1980s, additive production has come a long way. At first, it was mostly used for making prototypes and models. Designers loved how quickly they could make complicated shapes.

As technology got better, it could be used in more ways. When different materials like metals, ceramics, and even biocompatible substances were introduced, the options grew beyond plastic. This made things possible in fields like healthcare and aircraft.

The growth of digital tools was also very important. As software got better, it became easier than ever to make designs with lots of small details. Engineers could now test how things would work before they were made.

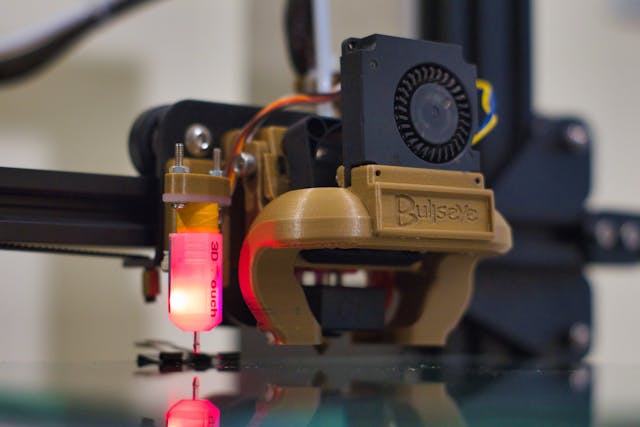

Additive Manufacturing Service do more than just make parts. They also make unique solutions that can be used by a lot of people. Businesses can quickly adapt to changes in the market and waste a lot less. The landscape is changing quickly as new companies enter the market every day with new ideas that change the way standard manufacturing methods are done.

Why using additive manufacturing services is a good idea

Additive manufacturing services have amazing benefits that are changing the way things are made. Design freedom is one of the best things about it. Complex geometries that were previously hard to make with old tools are now very easy to make.

In addition, these services help the environment. When compared to subtractive techniques, this method reduces waste by only using the materials that are needed. This not only saves money but also helps the environment.

Speed is also very important. Companies can get goods to market much faster than ever before because the time it takes to make prototypes and complete production runs is cut down by a large amount.

It’s also very cost-effective, especially for small runs or things that are made just for you. Companies save money on setup and tools while keeping the quality of the work good.

By letting designers and engineers make changes quickly during the planning process, additive manufacturing makes it easier for them to work together. In turn, this leads to new ideas that push the limits of many fields.

Businesses that use additive manufacturing services

Additive manufacturing services are making waves in many fields, showing how flexible and creative they can be.

The aerospace industry is one of the first to use these new tools. 3D printing is used by engineers to make parts that are light and safe while also improving fuel economy. This saves a lot of money and has less of an effect on the earth.

Manufacturers in the car industry use additive techniques to make custom parts and do rapid prototyping. Faster development processes are possible when designs can be changed quickly. It also makes it possible for customised cars that are made to fit the needs of each customer.

Thanks to additive manufacturing, healthcare is also going through a huge change. It is now possible to make custom limbs and implants much faster than ever before. This means that patients can get better fit and comfort. Surgeons are even planning surgeries ahead of time by printing 3D models of organs. This helps them be more precise during operations.

Building companies are looking into ways to use additive printing in the building process. 3D printing on a large scale lets you make complex structures with less waste than other ways. This offers not only better efficiency but also maybe more environmentally friendly building methods.

Companies that make consumer things have also found these services useful. Customers can now get a level of customisation that wasn’t possible before, from one-of-a-kind clothes to custom home decor.

As more and more industries try out additive manufacturing services, it’s clear that this technology has the potential to change everything, from how goods are designed and made to how innovation moves forward.